Sign Manufacturing for Multi-Site Projects

Sign Manufacturing: Finding the Right Partner for Your Business

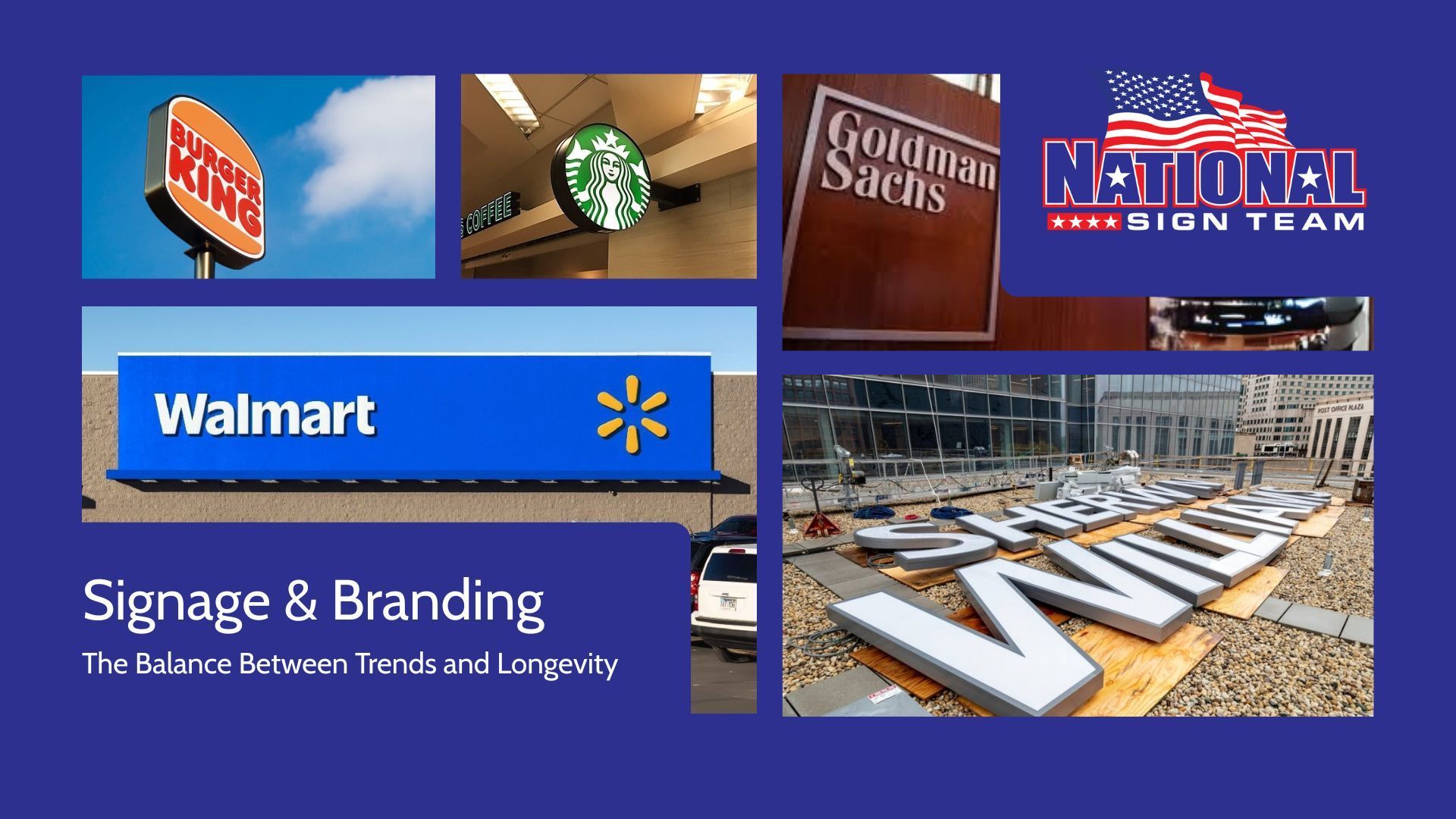

Choosing the right company to manufacture your signs can be a daunting task. With so many options, it's crucial to partner with a manufacturer that understands not only your brand vision but also the complexities of modern sign production. From material choices to installation logistics, there are several key factors to consider. For brand managers, site managers, and directors of construction, the challenge often lies in navigating the sign manufacturing process, understanding the available options, and ensuring you get a durable product that meets your budget and quality expectations.

Materials and Technologies in Modern Sign Manufacturing

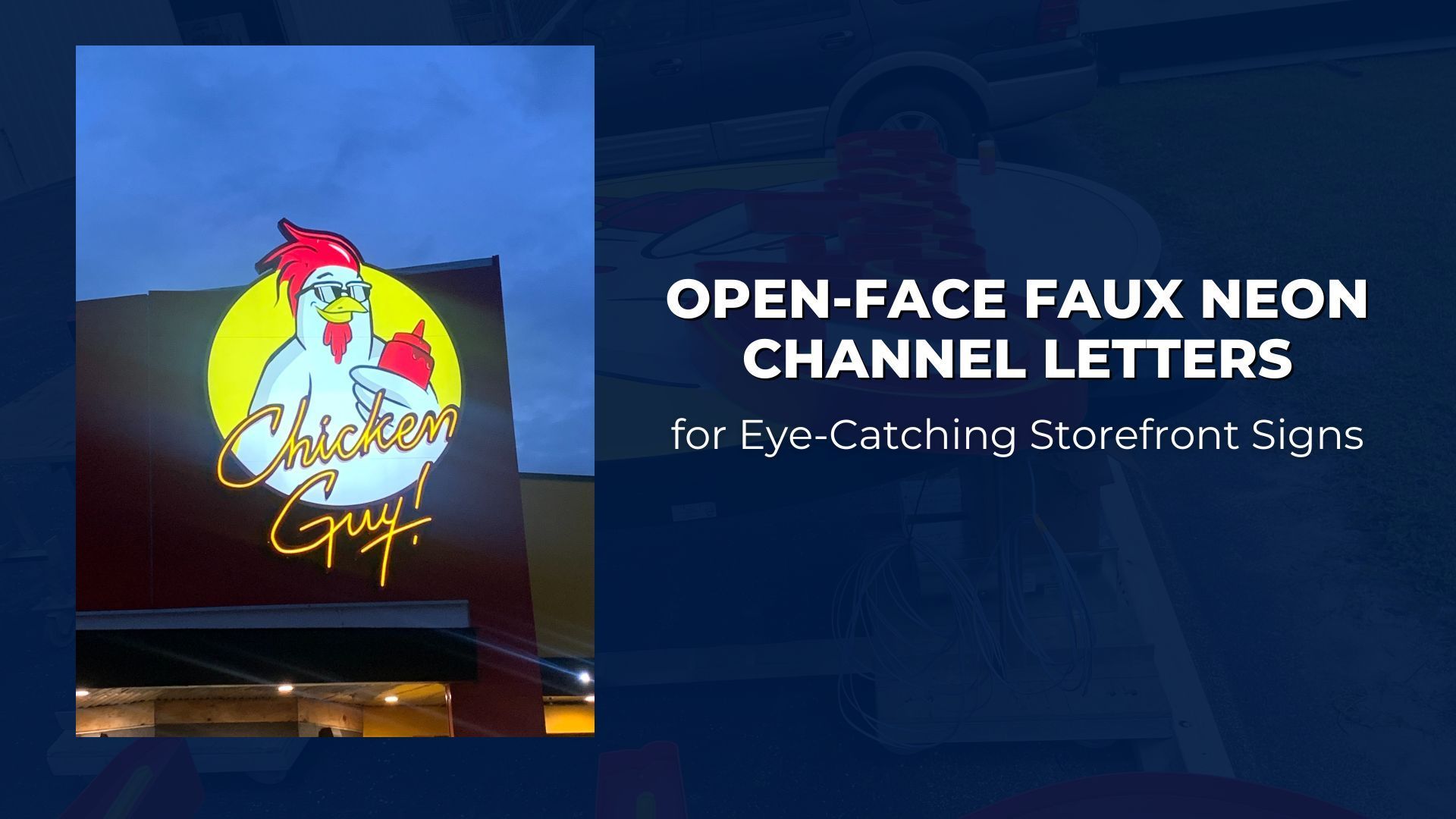

The latest advancements in sign manufacturing offer a wide array of materials and technologies that are transforming the industry. One of the most popular trends is the integration of LED and digital signage, which provides energy-efficient, dynamic displays that are perfect for large-scale projects. Eco-friendly materials, such as recycled plastics and sustainable metals, are also gaining traction as companies aim to reduce their environmental impact.

The use of durable materials ensures that signs are long-lasting and low-maintenance, which is a significant benefit for brand managers overseeing multi-site projects. These technologies not only help maintain brand consistency but also offer cost savings in terms of reduced maintenance and replacement needs.

Here's a table that breaks down Materials and Technologies in Modern Sign Manufacturing, focusing on the different options and their benefits:

| Material / Technology | Description | Benefits | Ideal For |

|---|---|---|---|

| LED Signage | Energy-efficient lighting that offers bright, clear displays | - Long lifespan - Low power consumption - Versatile designs | Large-scale signage Outdoor displays |

| Digital Signage | Dynamic, changeable content displayed on screens | - Easily updated - Interactive options - Attention-grabbing | Retail environments Public spaces |

| Eco-Friendly Materials | Recycled plastics, metals, and other sustainable materials | - Reduces environmental impact - Meets green certification requirements | Brands focused on sustainability |

| Acrylic | Lightweight, durable plastic used for signs | - Customizable - Weather-resistant - Cost-effective | Indoor and outdoor signage |

| Aluminum | Lightweight, rust-proof metal used in many sign applications | - Durable - Weather-resistant - Low maintenance | Outdoor signs Building facades |

| Vinyl Graphics | Printed graphics applied to various surfaces | - Cost-effective - Easily replaced - Customizable | Window signage Temporary promotions |

| LED Backlighting | Lighting placed behind signage to enhance visibility | - Energy-efficient - Enhances visibility - Modern aesthetic | Storefronts Interior signage |

| Digital Printing on Materials | High-quality, large-format printing on various materials | - High resolution - Custom designs - Fast production | Banners Custom wraps Billboards |

| Powder-Coated Steel | Steel treated with powder coating for durability and color variety | - Long-lasting - Corrosion-resistant - Custom color options | Industrial signs Outdoor use |

This table highlights the modern materials and technologies used in sign manufacturing, along with their benefits and best applications for multi-site projects and large-scale signage needs.

Cost-Effective Sign Manufacturing for Multi-Site Projects

Managing costs in sign manufacturing doesn’t have to mean compromising on quality. For multi-site sign projects, it's essential to find a balance between budgeting and long-term performance. Working with an experienced sign manufacturer can help identify cost-effective solutions without sacrificing quality or design.

Some budgeting tips include bulk ordering materials, opting for energy-efficient options like LED lighting, and working with a manufacturer who has a proven track record in handling large-scale, multi-location projects. By focusing on value and longevity, you can significantly reduce the need for frequent replacements, saving your business money over time.

Project Management and Coordination in Multi-Site Sign Manufacturing

Successful sign manufacturing for multi-site builds relies heavily on efficient project management. Coordinating multiple teams across various locations, adhering to tight deadlines, and ensuring consistent branding are just a few of the challenges that come with these large-scale projects.

At National Sign Team, we excel in managing complex sign projects that span multiple locations. Our project managers are experts in ensuring brand consistency and meeting project timelines. From the initial design phase to final installation, we work closely with our clients to provide a seamless experience across all sites, so you can focus on growing your business.

Schedule a Consultation with Our Sign Manufacturing Experts

Ready to bring your sign project to life? Schedule a call with the experts at National Sign Team to discuss your sign manufacturing needs. Let us help you create long-lasting, cost-effective signage solutions for your multi-site projects.

Tap to call: 727-859-1044

Tell Us a Little More About What You Need

Contact Us

We will get back to you as soon as possible.

Please try again later.

Tell us about your

next project...

Footer Contact

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | National Sign Team